Capacitive Ceramic Pressure Sensors for Vacuum Gauge in Semiconductor Industry

The application:

Vacuum gauges are essential instruments for measuring and monitoring vacuum level in various industries. In semiconductor manufacturing, vacuum gauges are widely used to monitor and control vacuum levels during processes, such as etching and deposition.

The challenge:

- Precision and accuracy requirements

Semiconductor manufacturing processes demand extremely high precision and accuracy in vacuum measurements. Even minor deviations in pressure can lead to defects in wafer processing, such as uneven etching or deposition. Vacuum gauges must operate with high sensitivity and stability to ensure consistent process control.

- Chemical resistance

Semiconductor fabs utilize a wide range of process gases and chemicals, which can be corrosive or reactive. Vacuum gauges must be compatible with these substances to avoid contamination.

Our solution:

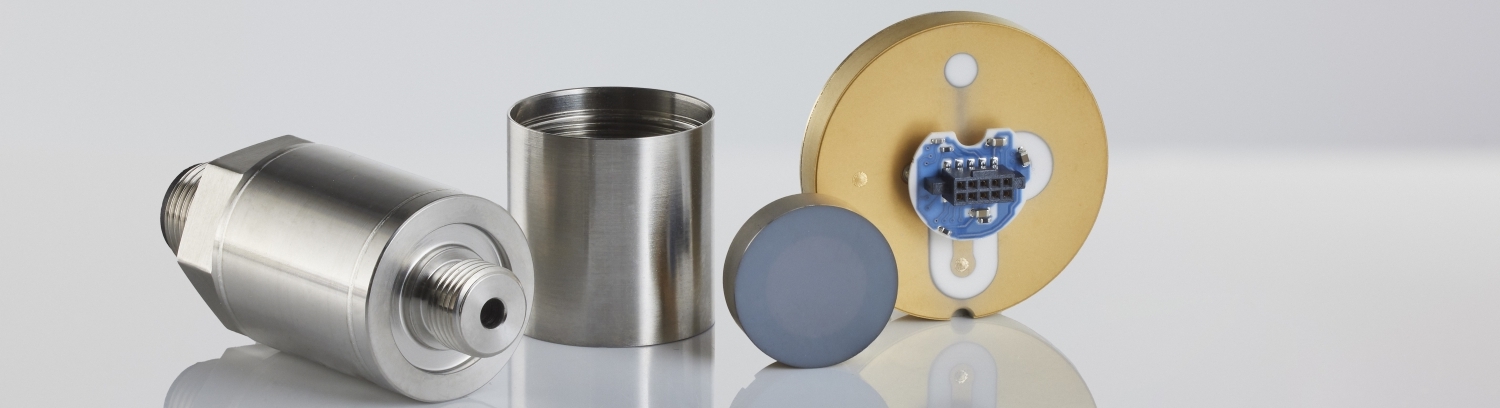

Compared to traditional technologies like Pirani gauges or piezoresistive pressure sensors, capacitive ceramic pressure sensors from the Ceracore family from Endress+Hauser offer following advantages:

- Exceptional resistence to environmental influences

Ceramic capacitive pressure sensors from Endress+Hauser are produced using high-purity (99.9% Al2O3) ceramic materials, which exhibit excellent corrosion and abrasion resistance. This allows them to operate reliably in harsh conditions, such as high temperatures, low pressures, and corrosive atmospheres.

- High sensitivity

The use of ceramic materials and capacitive sensing technology enables our sensors to detect extremely small changes and convert them into precise electrical signals. This high sensitivity allows for accurate measurement of vacuum levels. In vacuum gauge applications, where precise pressure measurements are crucial, the high sensitivity of capacitive ceramic pressure sensors ensures that even the slightest changes in vacuum can be detected and monitored.

- Long-term stability

Ceracore capacitive pressure sensors exhibit high zero point stability, which means they can maintain high measurment accuracy and reliability over long periods of use. This long-term stability is essential for vacuum gauges, as it ensures consistent and accurate measurements throughout the operational life of the instrument. For example, in industrial processes that require continuous monitoring of vacuum levels, the long-term stability of ceramic capacitive pressure sensors helps to minimize measurement errors and improve process control.

Endress+Hauser Sensors&Components has been developing customer-specific sensors for over three decades and focus the activities on partnership-based collaboration with customers. An interdisciplinary team from development, product management and sales handle implementing the users’ requirements in the best viable way. All information to the capacitive ceramic pressure portfolio can be found on the corresponding product page.