Differential pressure sensor USD50B

For accurate measurements and differential pressure monitoring

The differential pressure sensors USD50B with piezoresistive sensor and welded metal diaphragm are typically used in process and environmental industries. Applications are level, volume, or mass measurements in liquids or gases, differential pressure monitoring, e.g. filters and pumps, and flow measurement (volume or mass flow).

Benefits

The features of the versatile USD50B silicon differential pressure sensor at a glance.

- Measuring ranges

Measuring ranges from 100 mbar to 40 bar.

- Bridge output signal

Uncompensated bridge output signal (mV/V) with cable connection.

- High overload resistance

Overload resistance up to 160 bar/420 bar on one side, up to 240 bar/630 bar on both sides.

- High quality processed

Made of high-quality stainless steel (316 L).

- Reliable measurements

High accuracy, reproducibility, and long-term stability.

- Customized

Different diaphragm materials and filling oils can be selected on request.

Learn more about our customized Sensors & Components

Brochure: Customized Sensors & Components

(PDF, 1.5 MB)

Note on the design of differential pressure transmitters

The differential pressure sensors are the basis for the construction of high-quality differential pressure transmitters. The sensors are uncompensated and can be compensated and calibrated by the customer for the corresponding application. We are happy to advise you on the implementation process.

Differential pressure sensor USD50B

The differential pressure sensors USD50B with piezo resistive sensor and welded metal membrane are used in process and environmental industries. They measure level, volume and mass in liquids as well as differential pressure in e.g. filters and pumps as well as in flow applications (volume and mass flow).

Silicon differential pressure sensor, uncompensated bridge output signal with cable connection.

- Measuring range 10mbar to 40bar

- Bridge output signal (mV/V)

- Highest accuracy, reproducibility and long term stability

- High overload resistance of 160/420 bar* (one side) 240/630 bar* (both sides)

- 316L Version

- Different membrane materials and filling oils*

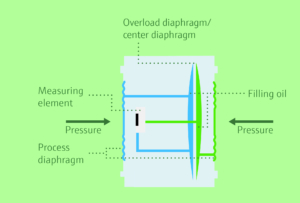

Technical structure of the USD50B.

Standardized measuring ranges:

- 0…100 mbar / 10 kPa / overload range: 160 bar (one side), 240 bar (both sides)

- 0…500 mbar / 50 kPa / overload range: 160 bar (one side), 240 bar (both sides)

- 0…3 bar / 300 kPa / overload range: 160 bar (one side), 240 bar (both sides)

- 0…16 bar / 1,6 MPa / overload range: 160 bar (one side), 240 bar (both sides)

- 0…40 bar / 4 MPa / overload range: 160 bar (one side), 240 bar (both sides)

Increased overpressure limit opitonal:

420bar (one side), 630bar (both sides)

Output signal and energy supply:

- Recommended: Constant current feed, <1mA

- Bridge resistance: 4.3…5.6kΩ (25°C)

- Output signal: 22…55mV/V (span)

Design size:

- Ø 55 mm x 40 mm

Operating conditions:

- Ambient/process temperature: -40 bis +85 °C

- Storage temperature: -40 bis +85 °C

Further information:

The differential pressure sensors are the base for the design and construction of high quality differential pressure transmitters. The sensors are uncompensated and can be compensated and calibrated at customer site.

* optional