Gauge and absoute pressure sensors

Individually adoptable. High overload resistance. High long-term stability.

Products for absolute and gauge pressure measurement

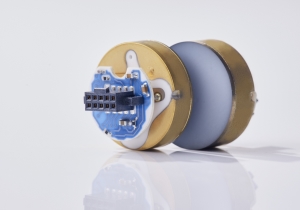

Ceracore USC30

Proven a million times over: Our capacitive ceramic measuring cell with an outer diameter of 17.5 mm.

Ceracore USC70

Proven a million times over: Our capacitive ceramic measuring cell with an outer diameter of 17.5 mm.

Ceracore UTC30

Proven a million times over: Our capacitive ceramic measuring cell with an outer diameter of 17.5 mm.

Over 30 years of experience in gauge and absolute pressure measurment

Our ceramic capacitive pressure sensor with patented technology is characterized by its standardized measuring ranges from 100 mbar to 100 bar, outstanding overload resistance and long-term stability, and by exceptional analog and digital available output signals. Thanks to special customer-specific modularity, our ceramic sensors are used in many industrial fields.

- Environmental Industry

A gauge pressure sensor is used to measure groundwater and wastewater levels in environmental engineering.

- Laboratory and research

An absolute pressure sensor is commonly used for vacuum control and many other applications in laboratory environments.

- Medical Technology

The high accuracy and long-term stability of our absolute pressure and gauge pressure sensors are valued in medical technology.

- Energy Industry

Gauge pressure measurements of the ceramic pressure sensing element optimize efficient and cost-saving energy production in power plants.

- Shipbuilding Industry

Our ceramic pressure transducer meets the unique requirements for level measurement of ballast and cargo tanks.

- Construction Industry

Ceramic capacitive pressure sensors detect before subsidence of buildings, tunnels, and other structures.

Learn more about our customized Sensors&Components

Brochure: Customized Sensors & Components

(PDF, 1.5 MB)

Know-how from the product idea to series production

Whether engineering, including prototype production, the implementation of a zero-defect quality target in series production, or reliable just-in-time delivery: With our services, we accompany you along the entire value chain. Individually and in line with your requirements.

Over 30 years of experience in absolute and gauge pressure measurement

With over 30 years of expertise in process measurement technology and an efficient application team, we develop top solutions for our customers that are easy to integrate and industrialize, offering both analog and digital output signal interfaces.

Thinst to know about absolute pressure or gauge pressure measurement

What does absolute pressure mean?

When it comes to pressure measurement technology, we differentiate between different measuring ranges such as absolute pressure, relative pressure and differential pressure:

If you want to measure the absolute pressure, 0 bar is used as the reference point. This would correspond to the pressure in an absolute vacuum, which of course would only be theoretically achievable. The starting point of the measurement is accordingly at 0 bar, abs. With an absolute pressure sensor, I can now, for example, determine the ambient pressure.

How to measure with an absolute pressure sensor?

With our capacitive ceramic absolute pressure sensors, the reference vacuum (6 X 10 -6 mbar) that is generated during the manufacturing process is retained in the sensor. In relation to the vacuum, this enables permanently stable and accurate pressure measurements.

What does relative pressure mean? How to measure it?

The existing ambient pressure forms the basis for measuring the relative pressure. Accordingly, the values are e.g. dependent on the barometric pressure or the altitude of the measuring point, because the air pressure is lower the higher the measuring point is.

How to measure with a relative pressure sensor?

With gauge pressure sensors, the rear of the process isolating diaphragm is vented. The sensor thus measures the overpressure relative to the prevailing atmospheric pressure.

How does Ceracore – pur ceramic capacitive pressure sensor work?

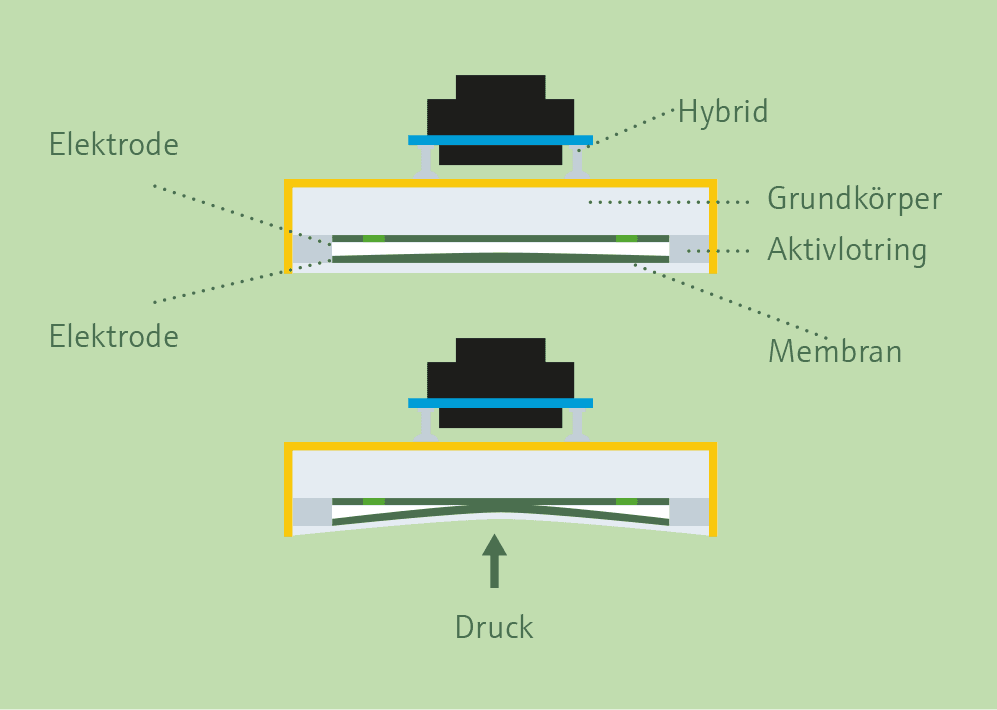

The Ceracore sensor is based on the capacitive measuring principle. The internally metallized membrane and the base body form the components of a plate capacitor. If the sensor is subjected to pressure, the distance between the membrane and the base changes. This leads to a change in capacitance. This change is converted by the evaluation electronics into a linearized and temperature-compensated output signal. The capacitive ceramic measuring technology offers you a number of advantages for measuring absolute pressure or gauge pressure.

Ceramic pressure measuring cell – structure: How is it composed?

The Ceracore sensor is based on the capacitive measuring principle. The internally metallized membrane and the base body form the components of a plate capacitor. If the sensor is subjected to pressure, the distance between the membrane and the base changes. This leads to a change in capacitance. This change is converted by the evaluation electronics into a linearized and temperature-compensated output signal. The capacitive ceramic measuring technology offers you a number of advantages for measuring absolute pressure or gauge pressure.

Our ceramic pressure measuring cell works on the basis of the capacitive measuring principle. Membrane and base form the components of a plate capacitor. If the sensor is subjected to pressure, the membrane flexes. This reduces the electrode gap and changes the capacitance of the capacitor. Evaluation electronics convert this change into an electrical output signal.

How can a ceramic pressure cell be individualized?

We build a ceramic pressure measuring cell step by step: Please use our MySensor configurator. There you can enter information about the sensor type, the desired measuring range, the output signal and the required connections, as well as selecting the additional equipment. After you have configured your individual sensor or the appropriate ceramic pressure measuring cell, we will work out a final pressure sensor or pressure transducer for you based on your information.